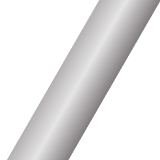

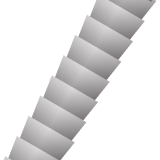

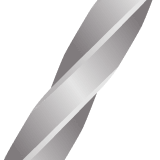

Nail shank types

| Smooth. Nails with smooth shank requires the least resistance while hammering the nails. |

| Ring. Nails with ring shank creates a ”locking” effect. This means that the hammered nail locks into place. |

| Screw. Nails with screw shank are more suitable for working with hard wood, as this shank reduces the probability of wood splitting because the hammered nail rotates like a screw and spreads it to the sides without tearing the wood fibres. |

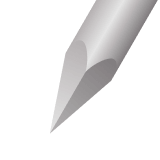

Nail cutting point

| Diamond. The diamond point nails are the most used nails. When this nail is hammered, the point fits into the wood much more easily. |

| Clinch. The clinch point nails mostly are used to produce wooden pallets. The nail with clinch point rests on a metal sole and bends easily (takes the shape of a hook). In this way, the nail “locks” and makes it much more difficult to pull it out. |

| Blunt/no point. The blunt point nails prevent the wood from splitting if the nail is hammered too close to the edge of the board. The blunt point nail pierces the wood fibres while the diamond point nail operates on the wedge principle and can easily crack the wood. |

Finish

| Bright (no coating). Nails without any coating are mostly used for interior work where the dry environment is more frequent, and the nails are not affected by any physical factors. |

| Vinyl coated. The vinyl reduces the friction between the nail and the wood, so the nail is hammered easier and faster. The heat generated from the nail during nailing “sticks” the vinyl to the wood. Such nails become much more resistant to the traction force. |

| Electro galvanized. This method of coating protects nails from a variety of nature factors, so nails can be used to fasten outdoor structure. |

Different types of coils

Flat vs Conical. They both perform the same function, and the main difference lies in what nail guns they will be used.

Different nail guns have a significant part in both flat and coil nails, as they either take one type or the other. If coil nails are used in the wrong gun, it is going to result in jamming and misfiring.

Jumbo coils. Are used for automated nailing machines in wooden pallet manufacturing.

Plastic collated nails vs paper collated nails. Both nail types can be used for the same nail gun as long as they are the same degree as the nailer and match the length set for the gun.

Difference between collation

Plastic strip collated nails

- Resistant to water and temperature damages.

- Great for outdoor use

Paper tape collated nails

- Holds more nails per strip

- Less jamming

- Leaves no debris

- More compact